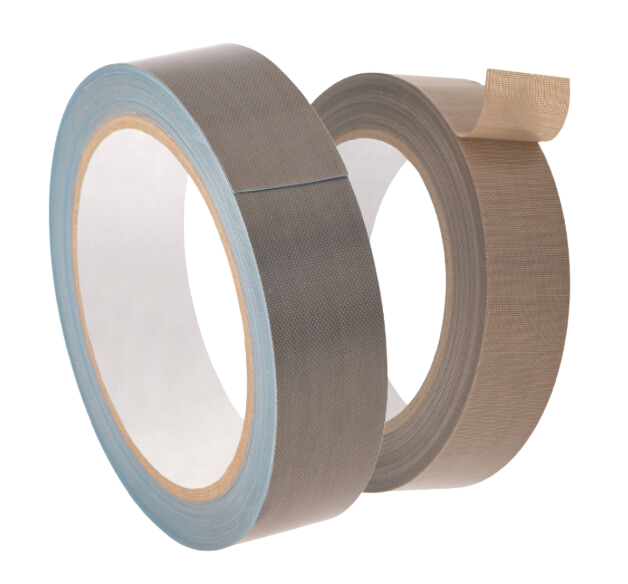

PTFE Adhesive Tape

PTFE coated adhesive tapes are high-performance materials designed for demanding industrial applications. These tapes are made by coating a base material - such as skived PTFE film or PTFE-coated glass fabric - with a silicone or acrylic adhesive. This construction delivers a unique combination of properties:

Exceptional non-stick and low-friction surfaces, making them ideal for use as release liners, conveyor belts, and in heat sealing operations.

Outstanding chemical resistance, allowing them to withstand exposure to oils, acids, solvents, and other harsh substances without degradation.

High temperature tolerance, with many tapes capable of continuous operation in environments up to 260°C (500°F), and some grades suitable for even higher temperatures.

Excellent dimensional stability and tensile strength, especially in PTFE-coated glass fabric variants, which resist stretching and tearing under mechanical stress.

Electrical insulation properties, making them suitable for coil and capacitor wrapping, composite bonding, and masking in electronic manufacturing.

PTFE adhesive tapes are available in various grades and constructions to suit different application needs, including premium grades for maximum PTFE content and release performance, and standard grades for general-purpose non-stick applications. They can be supplied with or without a liner, depending on installation requirements, and can be custom slit to any width for specific uses.

Brown International Ltd can supply PTFE coated adhesive tapes sourced from trusted manufacturers, ensuring access to a wide range of specifications and customisation options.

Step-by-Step Application Guide

1.Prepare the surface

Start by cleaning the surface thoroughly. Use a clean cloth and a suitable solvent to remove any contaminants like grease, oil, or dust.

2. Measure and cut

Measure the required length of tape and cut it to size for the area you need to cover.

3. Remove the release liner

Peel off the yellow corrugated release liner to expose the adhesive backing.

4. Apply the tape

Carefully position and apply the tape to the surface, ensuring it is aligned properly and covers the intended area completely. Press gently for optimal adhesion.

5. Smooth out imperfections

Use a roller or flat tool to eliminate air bubbles or wrinkles, ensuring a smooth, even application.

By following these steps, you can achieve a professional-grade finish every time. At Brown International, we supply high-quality PTFE adhesive tapes designed for industrial precision and durability. Contact our team today to learn how our products can enhance your operations. With their non-stick surface and heat-resistant properties, our tapes are built to perform under pressure.

The choice between a liner or no liner for PTFE adhesive tapes significantly impacts both handling and application:

With Liner:

A liner acts as a protective layer over the adhesive, preserving its tackiness and preventing contamination until the tape is ready for use. Liners enable easier handling, precise positioning, and clean processing, especially in production environments where tapes are die-cut, kiss-cut, or custom slit to narrow widths.

Without Liner:

PTFE tapes supplied without a liner are ready for immediate application, which can be advantageous for manual or high-speed automated processes where a liner would slow down production. However, tapes without a liner are more susceptible to premature adhesion, contamination, or damage during handling and storage. They are less suitable for applications requiring intricate die-cutting or precise placement, as the adhesive is always exposed.